In Depth Understanding of Sandblasting from Now

In Depth Understanding of Sandblasting from Now

We don't frequently refer to the term sandblasting in daily life, but it is applied to all aspects of our life. So do you really know what is sandblasting? To be familiar with it, the following introduction would be helpful to you.

The Abrasive Blasting

Brief Introduction

Abrasive blasting is the process of surface finishing by propelling media at a high velocity toward it. It is a quick and simple way to remove surface contaminants from metal, rubber, or plastic.

Abrasive blasting is commonly performed in closed environments such as blasting chambers or cabinets, or on open sites like on a boat, building, and bridge, etc.

The Types

Blasting has many general types according to different media:

Sandblasting

Wet abrasive blasting

Vapor blasting

Bead blasting

Dry-ice blasting

Blasting has three media delivery systems:

Air blasting (pneumatic)

Mechanical wheel (airless blasting)

Hydro blasting (pumped water)

Sandblasting

Brief Introduction

As a type of abrasive blasting, sandblasting is a surface treating process that generally contains an air compressor, abrasive particles, and a nozzle to spray abrasive particles under airflow in high pressure. It is named sandblasting for it blasts with particles of sand. When the sand particles are sprayed to the surface, they create the desired one.

History of sandblasting and nozzles

Sandblasting is a phenomenon that occurs in nature, not a human invention. Therefore, if we want to know when sandblasting appeared, it can be traced back to the beginning of the birth of the earth. Dust, sand, or particle blown up by the wind has the potential to change the surface of another object on impact. Take an example in our life, wind erosion.

In 1980, a man named Benjamin Chew Tilghman discovered this natural phenomenon when he observed the windows that had wind-blown sand on them. In addition, he designed a machine that can propel sand particles by pressurized air to the surface of objects. It is the first sandblasting machine called a straight bore nozzle.

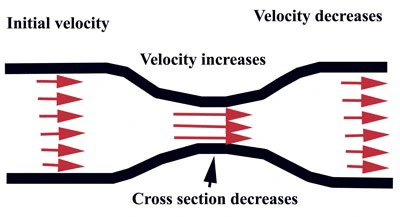

Swiss mathematician and physicist Daniel Bernoulli found that the air pressure difference can increase the speed of abrasive flow, which is known as Bernoulli’s Principle.

Then in the 1700s, this principle was supplemented by Italian Physicist Giovanni Battista Venturi. Until the 1950s, the Venturi nozzles appeared despite the Venturi effect being in existence long before.

Common Styles of Sandblasting Nozzles

For many years, various types of nozzles have been produced according to demands. For instance, the venturi nozzle is the best choice for efficient sandblasting. The internal pipe blasting nozzle is mainly used to clear the surface inside the pipe. The banana nozzle is mainly used to clean places that are narrow or difficult to handle with standard nozzles.

Venturi Nozzle: Venturi nozzles feature a wide blast pattern that promotes blasting more effectively. The Principle is that a reduction in pressure of fluid leads to an increase in the fluid’s velocity.

Water Induction Nozzle: It is characterized by the fluid mixing abrasive particles and water for surface treatment. Compared with other nozzles, it is friendly to health for suppressing dust.

Internal Pipe Blasting Nozzle: It is mainly used to clean the inner wall of the pipe that blasts in a cone pattern. Different types of nozzles are available for different pipe inner diameters. Sometimes additional tools are needed, such as collar sets, centering carriage, and rotating blast head carriage.

Banana Curved Nozzle: Its’ curved angle allows for access for sandblasting into hard or tight-fitting areas. It is a good choice for areas that are narrow or difficult to handle with standard nozzles