Introduction of sandblast water induction nozzle

Introduction of sandblast water induction nozzle

What is sandblast water induction nozzle

A sandblast water induction nozzle is a specialized nozzle used in sandblasting operations. It is designed to mix water and abrasive materials, such as sand or other media, to create a high-velocity stream for cleaning or surface preparation purposes. The nozzle has a unique design that allows it to draw the abrasive material into the water stream, creating a powerful and efficient blasting action. This type of nozzle is commonly used in industrial cleaning, surface preparation, and coating removal applications.

Sandblast water induction nozzle production

The production of sandblast water induction nozzles involves several steps. Here is a general overview of the production process:

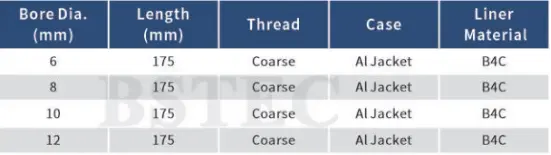

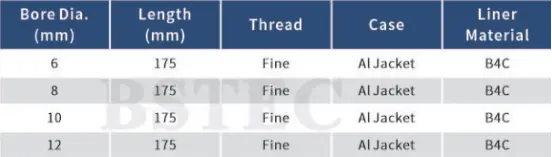

Design and Engineering: The first step is to design the nozzle according to the specific requirements and applications. This involves determining the nozzle size, shape, material, and other specifications.

Material Selection: The chosen materials must be durable, corrosion-resistant, and able to withstand high-pressure and abrasive environments. Common materials used for sandblast water induction nozzles include tungsten carbide, boron carbide, ceramic, and hardened steel.

Manufacturing: The manufacturing process typically involves machining the nozzle components from the selected materials. This may include turning, milling, drilling, and grinding operations to achieve the desired shape and dimensions.

Assembly: Once the individual components are manufactured, they are assembled together to form the complete sandblast water induction nozzle. This may involve welding, brazing, or using adhesives to join the components securely.

Quality Control: Quality control measures are implemented throughout the production process to ensure that the nozzles meet the required standards. This may include dimensional checks, pressure testing, and visual inspections.

Packaging and Distribution: After passing the quality control checks, the sandblast water induction nozzles are packaged and prepared for distribution. They may be sold directly to customers or supplied to distributors or retailers.

It's important to note that the specific production process may vary depending on the manufacturer and the type of sandblast water induction nozzle being produced.

Sandblast water induction nozzle application

Sandblast water induction nozzles are commonly used in various industries for cleaning and surface preparation purposes. Some of the common applications of sandblast water induction nozzles include:

Rust and paint removal: Sandblast water induction nozzles are used to remove rust, old paint, and other coatings from metal surfaces. The high-pressure water stream mixed with abrasive materials like sand or garnet effectively removes the unwanted layers without damaging the underlying surface.

Surface preparation: In industries like construction and manufacturing, sandblast water induction nozzles are used to prepare surfaces before painting, coating, or bonding. The nozzle helps in removing dirt, grease, and other contaminants, ensuring proper adhesion of coatings and improved surface quality.

Graffiti removal: Sandblast water induction nozzles are effective in removing graffiti from various surfaces like walls, bridges, and public spaces. The combination of high-pressure water and abrasive materials helps in eradicating the graffiti without causing damage to the original surface.

Concrete cleaning: Sandblast water induction nozzles are used to clean concrete surfaces, such as driveways, sidewalks, and parking lots. The nozzle can remove dirt, stains, and even tough substances like oil and grease, restoring the appearance and functionality of the concrete.

Ship hull cleaning: Sandblast water induction nozzles are used in marine industries to clean ship hulls. The nozzle helps in removing marine growth, barnacles, and other accumulated debris, improving the ship's performance and fuel efficiency.

Industrial equipment cleaning: Sandblast water induction nozzles are used to clean industrial equipment like tanks, pipes, and machinery. The nozzle can effectively remove scale, rust, and other deposits, ensuring optimal performance and prolonging the equipment's lifespan.

Automotive cleaning: Sandblast water induction nozzles are used in automotive industries for cleaning vehicle surfaces, engine parts, and other components. The nozzle can remove dirt, grease, and grime, improving the aesthetics and functionality of the vehicles.

Overall, sandblast water induction nozzles are versatile tools used for various cleaning and surface preparation applications across different industries.