Shot Blasting and Shot Peening

Shot Blasting and Shot Peening

Shot blasting and shot peening are common processes in the surface treatment world. If the industry uses metal parts, chances are it relies on shot blasting and peening to make things work. With similar names and styles of operation, they are often conflated. In reality, shot blasting and shot peening provide two entirely different functions.

SHOT BLASTING

Shot blasting is a process used for cleaning. Manufactured metal parts aren't ready for use right out of the mold. They often need a coat of paint, powder coating, or welding work. But before this can happen, the surface of the metal part must be clean.

Shot blasting prepares metal parts for further processing like painting or powder coating. This step is necessary to ensure the coat adheres properly to the part. Shot blasting can clean off contaminants like dirt or oil, remove metal oxides like rust or mill scale, or deburr the surface to make it smooth.

The process is undertaken using specialist equipment that shoots out rapid streams of abrasive material. Shot blasting uses a variety of different abrasives, ranging from glass to plastic to aluminum oxide. These tiny abrasives are shot out at high force, slowly chipping away at the unclean surface layer to reveal a cleaner layer underneath.

SHOT PEENING

Unlike shot blast cleaning, shot peening is used to relieve residual stress. Residual stress can occur from a manufacturing error. If a metal cools unevenly during a casting process, for example, this can place higher levels of stress upon neighboring parts. This can be problematic, as stress can compromise structural integrity. If not addressed quickly, cracks will likely start to form.

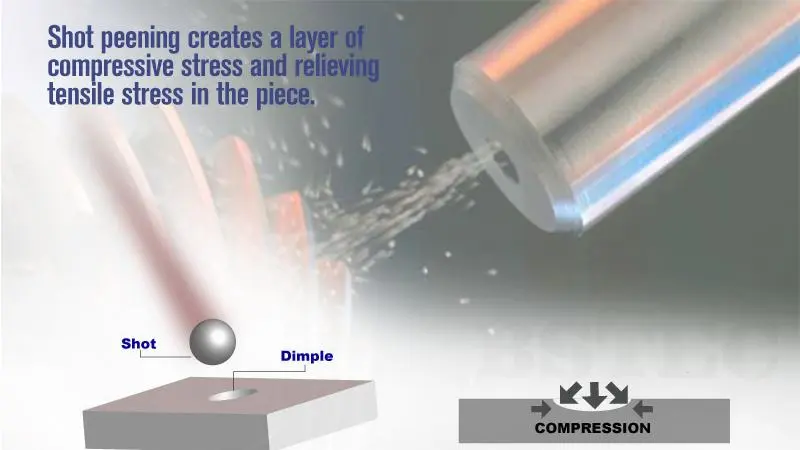

Shot peening works similarly to shot blasting by shooting rapid streams of tiny metal balls at a surface. The metal balls cause tiny indentations in the surface of the object, smoothing out the surface and relieving stress in the components. This expands the surface of the metal, creating a layer of compressive stress and relieving tensile stress in the piece.

Shot blasting and shot peening both involve shooting a stream of material against the part's surface. The biggest difference between shot blasting and shot peening is the end result. Shot blasting uses abrasives to clean or smooth the surface to prepare it for processing; shot peening uses the plasticity of metal to prolong the life of the part.

In shot peening, each shot acts as a ball-peen hammer. The process makes the surface of the metal part stronger and more resistant to cracks, fatigue, and corrosion. Manufacturers can also use shot peening to give the piece a textured surface.

Like with shot blasting, the choice of the shot depends on the application. Shot peening usually involves steel, ceramic, or glass shots. The material is reusable, making it an efficient and cost-effective process for strengthening metal parts.

Shot blasting and shot peening are both critical steps in the metal manufacturing process. Often, a part will undergo both before it’s ready for use.

And whether you use shot blasting or shot peening, abrasive nozzles are always involved in. In BSTEC, you will find full sizes and high-quality abrasive nozzles. www.cnbstec.com for more information.