Types of Blasting Nozzles

Types of Blasting Nozzles

With the development of the modern industry, blasting tools developed a lot. Nowadays, straight bore nozzles and Venturi bore nozzles are two kinds of blasting nozzles that are widely used to remove the hard materials on the workpiece. Other kinds of nozzles are also available. In this article, some types of blasting nozzles will be introduced.

Straight bore nozzle

Straight bore nozzles are the most conventional ones with the longest history. They consisted of a convergent end to concentrate the air and a flat straight section to outlet the air. They have the simplest construction and are easier to make. But they are facing the vertex atmosphere, which will decrease the pressure and velocity of the fluid wind when the wind is passing through the flat straight section. Different from the Venturi bore nozzle, straight bore nozzles don’t have a divergent end, so their blasting area is more concentrated and is not as large as Venturi bore nozzles.

Venturi nozzle

Venturi nozzles are combined with a convergent end, a flat straight section, and a divergent end. They can better deal with the vertex atmosphere and consume less pressure. With a divergent end, Venturi nozzles can produce higher velocity to blasting surface, which is more difficult to deal with. Compared with the straight bore nozzles, they can work with higher efficiency and consume less abrasive materials, but they are more difficult to produce because of the complex structure.

As we know, the straight bore nozzle has a long history, with more than 150 years. And the Venturi nozzle also developed around more than half of a century. To know, more types of nozzles merged.

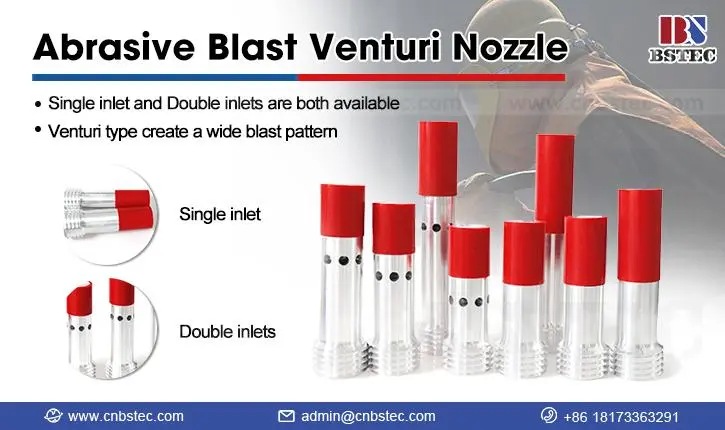

Types of venturi nozzles

The double Venturi nozzle is one of the new types, which is developed from the Venturi nozzle with one inlet. The double inlets Venturi nozzle has two parts. When they combine, there will be a small gap between the two parts. In this way, they can blast a larger area than the Venturi nozzle and are suitable to deal with the surface, which is difficult to remove.

Long Venturi nozzles and short Venturi nozzles are different from the length of their inlet. The nozzles with longer inlets can be applied to blasting the larger area.

These are some types of blasting nozzles. If you are interested in a blasting nozzle or want more information and details, you can CONTACT US by phone or mail at the left or SEND US MAIL at the bottom of the page.