Kenyelletso ea lisebelisoa tse mabifi le boholo

Selelekelan of E bohaleBlast Lisebelisoa le boholo

Mechini e phatsimang e sebelisa lisebelisoa tse fapaneng tsa ho hloekisa, sebopeho, kapa ho qeta ka ho fetola boitsebiso bo khahlano le thepa e phahameng. Tse ling tse tloaelehileng tse sebelisitsoeng li sebelisa li-a li-apties ka ho kenyelletsa:

Setsi sa Quartz: lehlabathe la quartz le entsoe ka lejoe le sithabetseng 'me le na le mathata a matle le ho apara. E theko e boima ebile e sebelisoa haholo indastering e makatsang.

Steel Grit le Steel Shot: Tsena li thata ho feta lehlabathe le boima ba ho tlosa likopo tse ngata joalo ka pefo ea tšepe bakeng sa ho penta.

Aluminium Oxide (Alumina): Adumina): Adumina o tsejoa ka thata ea eona e phahameng mme e ka sebelisoa bakeng sa lits'ebetso tsa metsi tse metsi le tse omeletseng. E loketse ho hloekisa le ho qeta matlo, khalase le meru e meng e thata.

Silicon Carbide: Siricon Carbides ke e 'ngoe ea li-atricias tse thata ka ho fetisisa mme e sebelisoa bakeng sa lits'ebetso tsa indasteri moo ho hlokahalang hore motho a etse hore ketso e hlokahalang.

Garnet: Garnet ke setlate sa tlhaho se fanang ka sehiloeng se sa senyeheng ka lerōle le lenyane, ho etsa hore e be le bohlokoa ba ho etsa liphetoho moo menahano ea tikoloho e bohlokoa.

Walnut shells le lijo tsa poone tsa corn Cob: Li-a li-ahlaketsing tsa walnut le lithunya tsa conet li-softer li sebelisetsoa ho ba le maemo a bobebe ntle le ho li senya.

Litsela tsa khalase: Litefiso tsa khalase li baka phetho e boreleli 'me hangata li sebelisoa ho etsa lintho tse qabolang, ho pola le ho peta maikutlo le lits'ebetso tsa peetsana le ho pepeta.

Media Media: Li-Alossives tsa polasetiki li sebelisoa bakeng sa ho phatloha ha bobebe ho tsekisang lithibelo tse sa fetoheng boemo ba karolo ea substrate.

Thunya ea tšepe: Thuto ea tšepe e se nang steel e ntse e jala tšepe e nang le steole le likhahla tse ling tse sa tsitsang, tse fanang ka phepo e khanyang ha u ntse u boloka thepa e ka tlase.

Lehloa le tsamaeang le khabone: Ena ke mokhoa o motle oa tikoloho oa setso, o sebelisa carbon dioxide ho etsa likokoana-hloko tse mpe tse tloselang likokoana-hloko tse tlosang likotsi.

Khetho ea tšilafalo e itšetlehile ka litlhoko tsa ho putlama, ho kenyelletsa le mofuta oa boitsebiso bo ntseng bo etsoa, ho fihlela lintlha tse lakatsehang le tse lakatsehang tsa tikoloho le tikoloho. Karolo e 'ngoe le e' ngoe e na le litšobotsi tse ikhethang tse etsang hore e be e loketseng lits'ebetso tse fapaneng.

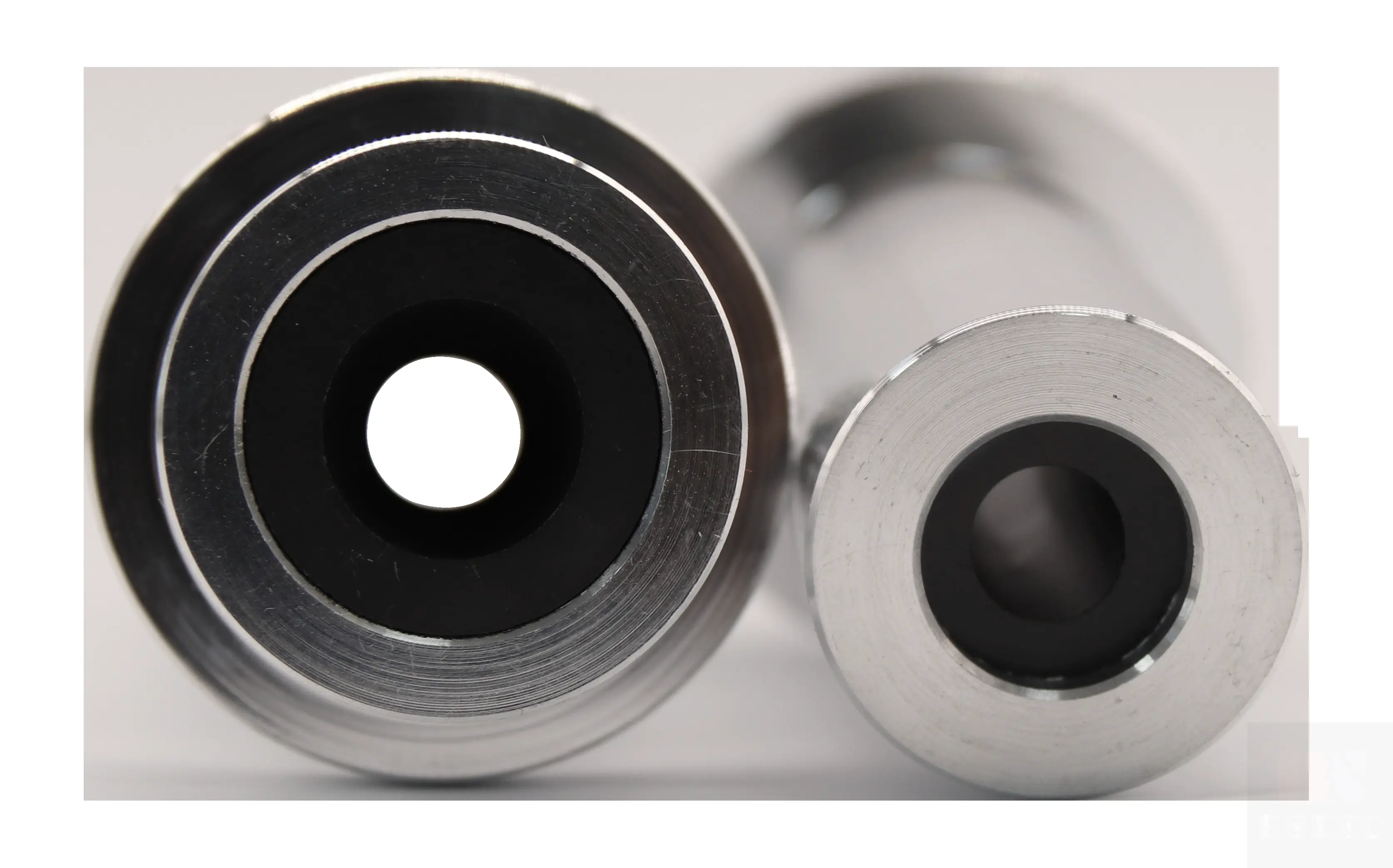

Mecha ea litaba e Chesa, e ngotsoeng ka mokhoa o tloaelehileng e bitsitsoeng, e sebelisoang metjeko ea mabokose e tla ka boholo bo lekanyang ho amohela lits'ebetso tse fapaneng le litlhoko tsa ho itukisetsa. Boholo ba tlhekefetso ho ka ama boleng ba ho qetela le katleho ea ts'ebetso ea ho ikatisa. Mona ke kakaretso e khuts'oane ea boholo bo tloaelehileng le ts'ebeliso ea bona e tloaelehileng:

Liaparo tsa masse tse ngata: tsena hangata li kholo ho feta boholo ba 20/40. Li-a li-aissives tsa mahoastse li sebelisetsoa lits'ebetso tse boima moo boemo bo tebileng bo hlokahalang. Li sebetsa bakeng sa ho tlosa makhapetla a boima, mafome a boima le tekanyo libakeng tse phahameng. Li-aisies tsa coarse li ka sebelisoa bakeng sa ho ba le maqhubu le masela bakeng sa pente e ntle ea pente kapa ho koaloa ke ho palama.

Li-arous tse mahareng: tsena li tloha ho 20/40 Meshi ho isa ho 80 mesh. Barekisi ba mahareng ba fana ka teka-tekano lipakeng tsa ho fokotsa matla le tšebeliso ea thepa. Li loketse mesebetsi e akaretsang ea ho hloekisa, ho tlosa khanya ho likokoana-hloko tse bohareng, le ho fana ka chefo ho libaka tse bohareng.

Li-abraiss tse ntle: hangata e nyane ho feta meshi ena, li-alate tsena li sebelisetsoa mesebetsi e metle haholo moo qetello e qetellang e hlokahala. Li loketse libaka tsa ho hloekisa ntle le ho fetola substrate, joalo ka ho tlosa pente e bobebe, oxida, kapa ho lokisa li-cookie tse tebileng ntle le ho tlohela li-grooves ntle le ho tlohela li-graove. Li-abaeli tse ntle li sebelisoa hape molemong oa ho fihlela mokhoa o boreleli.

Ho na le maiketsetso a matle haholo kapa a makgaitsk Li sebelisetsoa mosebetsi o boima haholo, joalo ka ho hloekisa libaka tse rarahaneng, ho nyala kapa ho qeta thepa e tebileng ntle le ho baka tšenyo. Likhatiso tse ntle haholo li ka sebelisoa hape ho itokisetsa meahong e mahlonoko moo boemo ba motho ba lokelang ho ba joalo ka yunifomo.

Khetho ea boholo ba masene e itšetlehile ka lintlha tse 'maloa ho kenyelletsa le boitsebiso bo phatlohileng, Likarolo tse nyane li ka sebelisoa ho likhatello tse tlase ho fokotsa tšenyo ea ho tlala, ha likaroloana tse kholo li hloka likhatello tse phahameng tsa ho fihlela phello e lakatsehang. Kamehla netefatsa hore boholo bo sa tloaelehang bo tsamaisana le lisebelisoa tsa sandblate li sebelisoa ho thibela tšenyo kapa ho se sebetse hantle.