Umhlahlandlela Wokufaka Izibambi Zokuhlanganisa/Izimbobho Epayipini

Umhlahlandlela Wokufaka Izibambi Zokuhlanganisa/Izimbobho Epayipini

Uma ungusonkontileka, izinkinga ezimbili ezinkulu ongazifuni esizeni somsebenzi izingozi, kanye nemishini iwohloka ngokushesha. Ingozi enkulu yinoma yikuphi ukungasebenzi okungenzeka okubandakanya umoya ocindezelwe. Amapayipi aqhumayo avamise ukuguga eduze kwezibambi ze-nozzle. Ingcindezi iphuma emigodini eyakhiwe ukuhlangana okufakwe ngokungafanele.Ngakho-ke ukufakwa ngendlela efanele kwama-couplings aqhumayo noma imibhobho epayipini eliqhumayo kubaluleke kakhulu.

Nazi ezinye izinyathelo zokuqinisekisa ukufakwa okufanele nokuphephile kwe-blast coupling noma izibambi zakho.

Isinyathelo 1: Qiniseka ukuthi unosayizi ofanele wepayipi le-blast hose nama-couplings aqhumayo

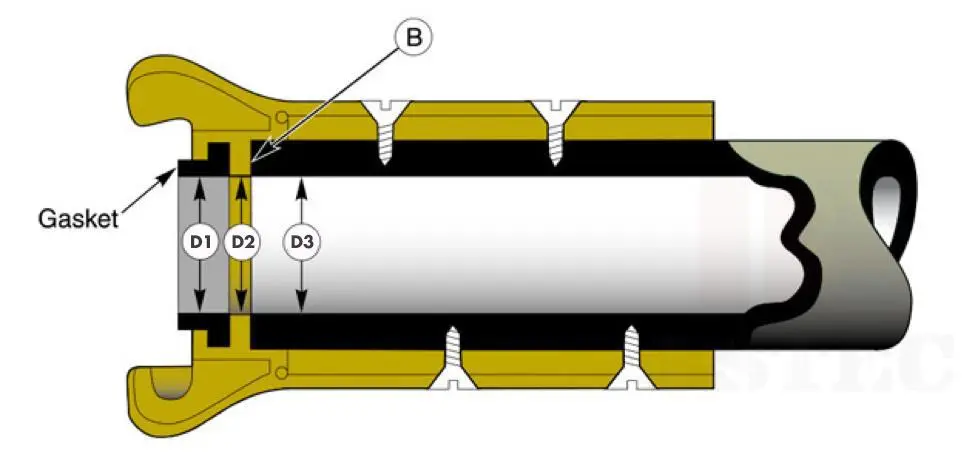

I-Blast Hose Bore (D3) kufanele ilingane (noma ibe ncane kune) i-Flange Bore(D2) kanye ne-Gasket Bore (D1). Lokhu kuzoqinisekisa ukuthi ukuhlangana akugqoki ngaphambi kwesikhathi, okushiya i-gasket ingasekelwe futhi ijwayele ukuvuza. Kunoma iyiphi ipayipi eliqhumayo elinebhore enkulu kuno-1-1/4" (32mm), sebenzisa ama-couplings anebhobo elikhulu.

Isinyathelo sesi-2: Sika isikwele se-hose hose

Iziphetho zamapayipi ngokuvamile azikona isikwele ukusuka embonini. Sidinga ukusebenzisa ithuluzi lokusika i-hose ukusika isikwele se-hose hose. Lokhu kubalulekile ukuthi iziphetho zepayipi lokuqhuma zisikwe zihlanzeke futhi zibe isikwele (flat) ukuze sikwazi ukuvimbela ukuhlangana okuzayo ukuvuza nokuguga ngaphambi kwesikhathi.

Isinyathelo sesi-3: Vala ngaphakathi kwesibambi esiqhumayo noma isibambi somlomo

Ukuze udale uphawu oluqinile emoyeni, kunconywa ukusebenzisa i-sealant ngaphakathi kwe-coupling noma i-nozzle holder. Esikhundleni sokusebenzisa njenge-glue yokunamathisela ukuze uvikele i-hose ekuhlanganiseni, injongo yayo eyinhloko ukuvala izikhala zomoya. Futhi qiniseka ukuthi le nhlanganisela yokuvala ongayikhetha yelapheke kahle ngaphambi kokuthi ufake ingcindezi kupayipi.

Isinyathelo sesi-4: Faka isibambi esihlanganisayo noma somlomo

Guqula okokufaka kuhambisane newashi, njengokungathi uyigoqa epayipini kuze kube yilapho isiphetho sepayipi sigudluzwa ngokuqinile ngokumelene ne-coupling flange noma phansi kwezintambo.

UKUHLANGANISA: Ipayipi eliqhumayo kufanele lifakwe lize liphume ngokuphelele.

ABABAMBE I-NOZZLE: Ipayipi eliqhumayo kufanele lifakwe kuze kube yilapho liguquguquka nephansi lezintambo.

Isinyathelo sesi-5: Hlanza noma iyiphi into ehlanganisiwe ye-sealant ngaphakathi kwepayipi

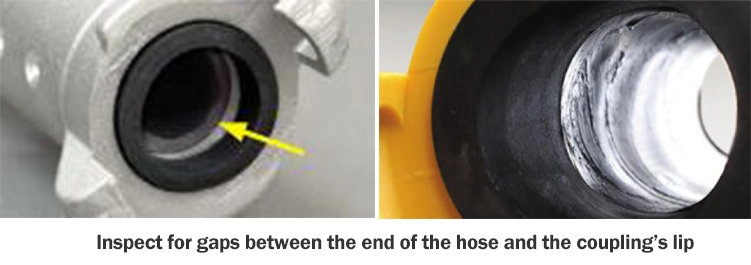

Isinyathelo sesi-6: Hlola izikhala phakathi kokuphela kwepayipi nodebe oluhlanganisayo

Hlola ukuthi ipayipi eliqhumayo liyagudla yini ku-coupling yonke indlela ukuqinisekisa ukuthi isikwe isikwele futhi yafakwa ngokuphelele.

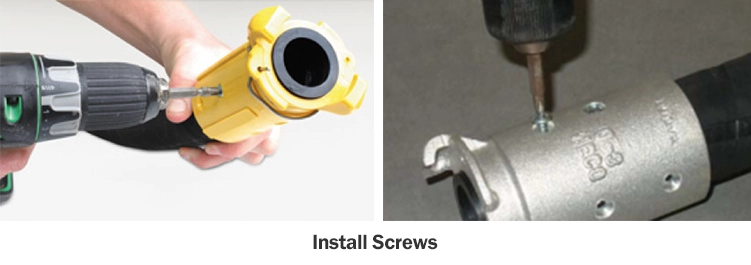

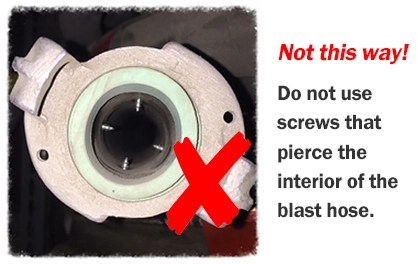

Isinyathelo sesi-7: Faka Izikulufo

Usebenzisa i-power drill, faka izikulufu. Qhubeka nokusonta izikulufu 2-3 ukuphenduka okungaphezu kwekhanda lesikulufu lihlangana nesibambi esihlanganisayo/nozzle ukuze uqinisekise ukuthi ipayipi lidonswa laqina odongeni lokuhlanganisa kuze kube yilapho ipayipi selidonselwe emuva ku-coupling. Kodwa ungaqinisi kakhulu futhi ungalokothi usebenzise izikulufu ezinde ngokwanele ukubhoboza ipayipi lonke ku-blast stream, ngaphandle kwalokho, izokunikeza izindlela zokuphunyuka zokucindezela komoya okuzokhuthaza ukuguga ngaphambi kwesikhathi noma ukwehluleka.

Isinyathelo sesi-8: Faka amadivaysi aphephile (ama-blast couplings kuphela)

Faka isiqeshana sokuphepha esine-lanyard kanye nokuhlola ukuphepha. Amapayipi aqhumayo afika engahlanganisiwe kuyilapho ecindezelwe ayingozi eyingozi yokuphepha.