Kusarudza Blasting Abrasive Media

Kusarudza Blasting Abrasive Media

Ese ari maviri akareruka uye epamusoro emidziyo madhizaini anoshandiswa mune abrasive blasting masisitimu. Zvakadaro, hapana system yaigona kushanda isina abrasive media. Nyaya iyi ndiyo mwoyo weabrasion blasting process, uye inowanikwa nenzira dzakasiyana dzakagadzirirwa kushandiswa kwakasiyana.

Nemhepo inoputika masisitimu, midhiya inopinda mumhepo yakamanikidzwa kubva mupoto kana mudziyo. Mavharuvhu anofambisa media stock mumhepo inoputika hose, uye recycling system inobvumira midhiya kuti idzoke. Centrifugal shot blasting systems inewo mudziyo wekubata. Iyi sisitimu inoshandisa mechanical feed kutumira midhiya mukati mevhiri rinotenderera uye panzvimbo yekurapa isati yatorwa nekudzokororwa.

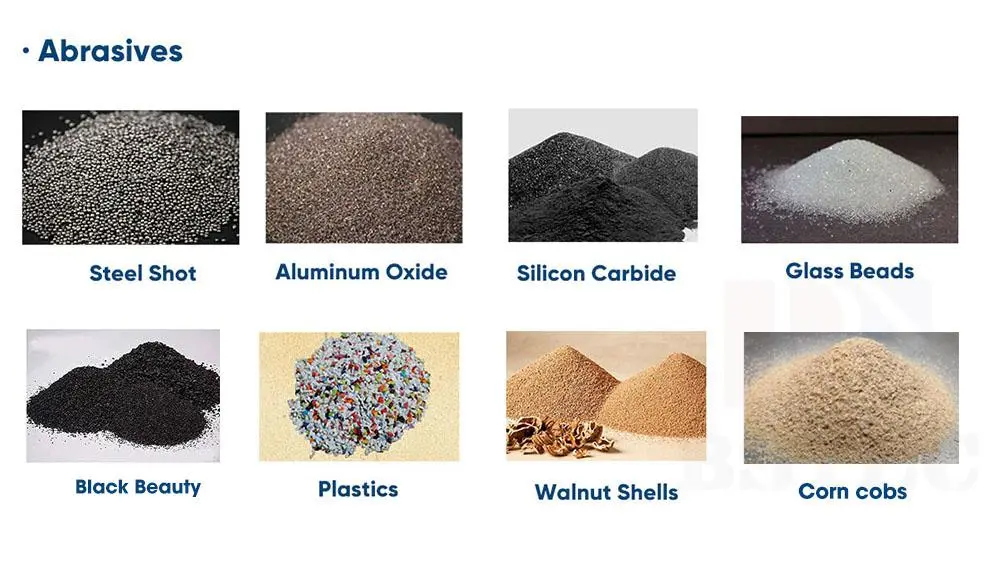

Abrasive zvinhu zvinogona kuva mineral, organic, ceramic, plastiki, kana simbi-based. Chekemikari yega yega inoita mabasa akashata uye ine makiyi abrasive properties.

Pane zvinhu zvina zvinoda kutariswa muabrasive blasting operations:

1. Chimiro:Media particle shape yakakosha kumagumo ekupedzisira. Zvimedu zvakaita denderedzwa hazvinyanyi kukwenya pane angular shapes.

2. SaiziMedia particle size inoyerwa mu "mesh." Uku ndiko kuongorora kunotemerwa nemaburi paskweya inch uko yakanaka midhiya saizi inosefa kuburikidza nemakomba akawanda mune mesh skrini kana ichienzaniswa neakakura zvidimbu.

3. Kuoma:Zvimedu zvakaoma semapfuti esimbi zvinopinda zvakadzika mukati memidziyo kupfuura midhiya yakapfava yakaita sezvidimbu zvepurasitiki. Izvo zvakakosha kuti kuputika midhiya kuomarara kuenderane nepamusoro kudzivirira kukuvara kusingadzoreki.

4. Density:Dense media particles ane huremu hwakawanda pahukuru pane lightweight material. Kufanana nekuoma, iyo chaiyo midhiya density yakakosha kuita basa nemazvo pasina kukanganisa kurapwa.

Imwe neimwe blast abrasive media material ine hunhu hwayo inodarika chimiro, saizi, kuoma, uye density. Kusarudzwa kwemidziyo yeMedia kunonyanya kuenderana nepamusoro ari kugadzirira kana kurapwa, kwete hazvo pamhando yemidziyo yeabrasive iri kushandiswa. Hezvinoi zvakajairwa zvinoshatisa zvemidhiya zvauchawana mumashandisirwo ekuputitsa abrasive:

· Simbi kupfura uye simbi grit:Simbi inopfurwa idenderedzwa ukuwo simbi grit ine angular shape. Iyo inonyatso shanda abrasive kune roughness yayo uye yakakwirira recyclability. Pamabasa anorema, hapana chinokunda mabrasives esimbi.

· Aluminium oxide:Aluminium oxide inoratidzira kuoma kwayo kwakanyanya uye simba. Kune dzakaoma nzvimbo dzinoda kukwenenzverwa, aluminium oxide ndiyo midhiya yakakwana. Iyo yakaoma, inogona kushandiswazve, uye yakaderera-mutengo.

· Silicon carbide:Ndiyo yakaomesesa abrasive material iripo. Iyi nhepfenyuro inouya muhukuru kubva pahupfu hwakatsetseka kusvika kune yakakora grit. Inokodzera zvakanaka mukuchenesa nzvimbo yakaoma zvikuru.

· Glass beads:Iro raundi soda-lime girazi. Kuenzaniswa nezvimwe zvinhu, girazi harina hukasha sekuputika midhiya sesimbi kupfura kana silicon carbide. Mabrasives egirazi mabhedhi ane kushushikana kushoma pamusoro pepamusoro kuti abudise inopenya uye satin matte mhando yekupedzisa.

· Black Beauty:Iyi isimbi yemarasha slag. Runako Rwakasviba rwakakasharara uye rwakakodzera marara anorema uye kubvisa pendi.

· Plastiki:Mabrasives akagadzirwa kubva mupurasitiki anosiyana muhukuru, chimiro, kuoma, uye density. Zvigadzirwa zvepurasitiki zvinosanganisira polystyrene uye polycarbonate. Iyo yakapfava abrasive iyo yakanakira yefiberglass kurapwa, mold, kana epurasitiki zvikamu zvekuchenesa.

· Makungu eWalnut:Black walnut shells akanakisa abrasives kune yakapfava simbi uye epurasitiki nzvimbo. Makoko eWalnut haadhure uye anowanikwa zviri nyore pamwe nekuita compost.

· Miguri yechibage:Kufanana nematehwe ewalnut, miguri yechibage yakapfava organic abrasives. Anoshandiswa panzvimbo dzakatetepa kubvisa zvinosvibisa segirisi, mafuta, uye grime pane kuita ngura nependi.