Marine Coating Kubviswa mu Shipyard

Marine Coating Kubviswa mu Shipyard

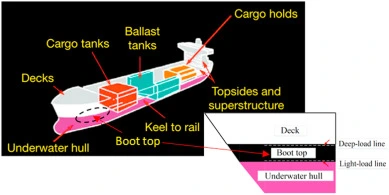

Theindasitiri yekutakurainobata kutakura 90% yekutengeserana kwenyika. Zvikepe zvepasirese zviripo zvino zvinosanganisira zvinopfuura zviuru zana zvezvikepe zvevatengesi, kusanganisira zvinotakura zvakawanda,matangi, midziyo, kutakura zvinhu, zvikepe, uye ngarava dzinotakura vanhu. Sezvinoratidzwa pamufananidzo uri pazasi, ngarava yevatengesi ine nzvimbo dzakasiyana dzakaita senge underwater hull, boot top area, decks, matangi eballast, topsides and superstructures, uye ngarava mukati. Mapendero akasiyana emugungwa akakosha uye akagadzirirwa kudzivirira nzvimbo dzengarava kubva mukuora, kupisa kana moto, uye kusvibiswa. A coating system anowanzo sanganisira akati wandei akaturikidzana: aprimer jasi, jasi rimwe kana anopfuura epakati, nejasi repamusoro.

Pasi pekuchengetedzwa kwemajasi, ngarava inogona kushanda kwehupenyu hwesevhisi ye20-30 makore. Zvakadaro, kushatisa uye kuita ngura kwenzvimbo yengarava kunoitika panguva yekufambisa kwemugungwa, izvo zvinoda kuti ngarava imirwe kuti igadziriswe uye kugadzirisa mukati memakore 3–5. Panguva yekugadzirisa ngarava, zvinhu zvekunze zviri pangarava zvakanamira nzvimbo zvakadai semafuta, girizi, munyu, zvipenyu zvemugungwa zvakanamirwa, uye slime, zvinosukwa nemvura ine simba guru, zvichiteverwa nekubviswa kwe ngura nemabhandi kuburikidza nekuchenesa kana kuputika kwakazara.

Abrasive blasting (i.e., grit blasting) inoshandisa mhepo, pressure yemvura, kana simba recentrifugal kufambisa mhepo yeabrasive pamusoro pepamusoro kubvisa ngura, chigayo, tsvina, nependi dzakasakara, uye kugadzira nzvimbo yakaoma. profile. Nonabrasive blasting inobvisa tsvina yepamusoro uye machira pasina kushandisa mabrasives. Nekudaro, haigone kugadzira chimiro chepamusoro, uye nekudaro, inonyanya kushandiswa kune yekare profiled nzvimbo pane nyowani simbi.

Kwemakore akawanda, kuputika kwakaoma kweabrasive kwave iri nzira yakanyatsoshanda uye ine hupfumi inoshandiswa panzvimbo huru kubvisa pendi dzakasakara, ngura, uye humwe hutsvina. Mufananidzo (a) unoratidza mashandisirwo ari nyore ekushandiswa kunonyanya kushandiswa kwemhepo inoputika, umo mweya wakadzvanywa unoshandiswa kufambisa zvinhu zvinopusha kuenda kunzvimbo yekushanda. Kuputika kwemhepo kunoshandiswa munzvimbo yakazaruka nokuti midziyo yakakura zvikuru kune imwe nzvimbo yemukati. Abrasive media senge maminerals chaiwo (e.g., garnet ne olivine), metallic grits, coal slag, copper slag, nemamwe metallurgical slags ave achishandiswa mushure mekurambidzwa kwe silica sand nekuda kwe silicosis.. Muchiitiko ichi, huwandu hwemarara hwakasimba hunogadzirwa, hunosanganisira mabrasives akasvibiswa uye mapepa epende. Kupfuurirazve, yakavhurika-mhepo yakaoma abrasive blasting ine dambudziko rinowedzera maererano nekuteerana nehurumende uye yemunharaunda hutano uye nharaunda mitemo. Kuti izvi zviitike, kuedza kwakaiswa mari kuderedza kuburitswa kweguruva, kusanganisira kushandisa vacuum blasting, kushandiswa kweguruva rinodzvanya., uye kuvandudzwa kwe (semi-)otomatiki masisitimu. Mitemo yeHurumende neyemuno iri kuwedzera kurambidza kushandiswa kwemhepo yakavhurika kuvhuvhuta, zvichikurudzira kuvandudzwa kwezvigadziriso zvitsva zvetekinoroji sekutsvaga dzimwe nhepfenyuro nehunyanzvi.

Nzira dzekuputira dzakanyorova dzakagadzirwa kuti dzideredze kuburitsa huruva uye kugadzirwa kwemarara. Nzira dzekunyorova dzinoshandiswa muindasitiri yekugadzira ngarava dzinogona kukamurwa kuita zvikamu zviviri: kuputika kwemhepo nekuwedzera kwemvura (kureva, kuputika kwemhute kana kuputika kwemhepo), uye kuputika kwemvura nekuwedzera abrasive (kureva, hydraulic blasting). Mu hydraulic blasting (Mufananidzo (b)), mvura ine simba guru (200–700 bar) inoshandiswa kutyaira mabrasives pamusoro. Kusiyana neizvi, mumhepo inoputika (Mufananidzo (c)), mabrasives akaturikwa mumvura anoratidzwa nejeti remhepo yakamanikidzwa, kana kuti zvishoma, pombi inotsikirira centrifugal. Kuenzaniswa ne hydraulic blasting, slurry blastingiri 'kupfava', inowana kupera kwakanaka, uye ine mvura shoma yekushandisa. Nekudaro, kana zvichienzaniswa neyakaoma abrasive nzira, ese maviri matekiniki anoburitsa imwe yakawedzera tsvina rwizi, i.e., tsvina.

Imwe nzira yakakurumbira yekuputika kwemvura ndeyekuputika kwemvura pasina chero abrasives, iyo inonzi mvura jetting. Ultrahigh pressure (UHP) jetting yemvura ndiyo imwe yenzira dzinokurumidza kukura dzekugadzirira dzinoshandiswa mumayadhi ekugadzirisa ngarava. MuUHP jetting yemvura (Mufananidzo (d)), pombi yeUHP inomanikidza mvura yakachena kuti iite yakanyanya kudzvanya (kazhinji 2000 bar sedikidiki)eam yobva yaipfuudza nemumiburi inotenderera ine tunhu tudiki, ichiita mhepo inoputika inoputika kubvisa pendi dzakasakara, ngura, uye zvimwe zvinosvibisa pamusoro. Iyo sisitimu inowanzo shongedzerwa nevacuum suction system yekuunganidza mvura yetsvina uye tsvina pendi machipisi. Pasina kushandiswa kweabrasive media, huwandu hwemarara anogadzirwa hwakaderedzwa zvakanyanya. Zvakadaro, pane-saiti yekudzokorodza mvura system yakakosha pakushandiswa kwakasimba kwemvura yakachena.

Dzimwe nzira dzakaita se dry ice blasting, cryogenic N2jetting, plasma depainting, uye laser depainting zvakagadziridzwa uye zviri kuwedzera kushandiswa mukubvisa coating kudzikisa marara.

Kugamuchirwa kushanyira webhusaiti yeduwww.cnbstec.comkuti uwane rumwe ruzivo.