Ukukhetha i-Blasting Abrasive Media

Ukukhetha i-Blasting Abrasive Media

Kokubili imiklamo elula nethuthukisiwe yemishini isetshenziswa ezinhlelweni zokuqhumisa eziqhumisayo. Nokho, ayikho isistimu engasebenza ngaphandle kwemidiya elimazayo. Le nto iyinhliziyo yenqubo yokuqhunyiswa kwemihuzuko, futhi itholakala ngezindlela ezahlukene ezihloselwe ukusetshenziswa okuhlukahlukene.

Ngezinhlelo zokuqhuma komoya, imidiya ingena emoyeni ocindezelwe isuka ebhodweni noma esitsheni. Amavaluvu afaka isitokwe semidiya epayipini eliqhumayo, futhi uhlelo lokugaywa kabusha luvumela abezindaba ukuthi babuye. Amasistimu okuqhunyiswa kwe-centrifugal nawo anesitsha sokubamba. Lolu hlelo lusebenzisa okuphakelayo komshini ukuthumela imidiya esondweni elijikelezayo nasendaweni yokwelapha ngaphambi kokuthi iqoqwe futhi igaywe kabusha.

Izinto eziqhumayo zingaba ngamaminerali, i-organic, i-ceramic, ipulasitiki, noma isisekelo sensimbi. Isizinda samakhemikhali ngasinye senza imisebenzi ethile elimazayo futhi sinezinto ezibalulekile zokugwaza.

Kunezindawo ezine okufanele zicatshangelwe emisebenzini yokuqhuma okulimazayo:

1. Isimo:Umumo wezinhlayiya zemidiya ubalulekile ekuqedeni kwendawo yokugcina. Izinhlayiya ezimise okwendilinga azigwagwisi kakhulu kunezimo ze-angular.

2. Usayizi:Usayizi wezinhlayiya zemidiya ulinganiswa “nge-mesh.” Lokhu ukuhlola okunqunywa izimbobo kuyintshi ngayinye yesikwele lapho usayizi wemidiya ehlunga ngezimbobo eziningi kusikrini semeshi uma kuqhathaniswa nezinhlayiya ezinkulu.

3. Ukuqina:Izinhlayiya eziqinile njengezinhlamvu zensimbi zingena zijule ezintweni ezisetshenziswayo kunemidiya ethambile njengezinhlayiya zepulasitiki. Kubalulekile ukuthi ukuqina kwemidiya eqhumayo kuhambisane nendawo ukuze kugwenywe umonakalo ongeke ulungiseke.

4. Ukuminyana:Izinhlayiya zemidiya eziminyene zinesisindo esiningi ngosayizi ngamunye kunezinto ezingasindi. Njengobulukhuni, ukuminyana okufanele kwemidiya kubalulekile ukwenza umsebenzi ngempumelelo ngaphandle kokubeka engcupheni indawo yokwelapha.

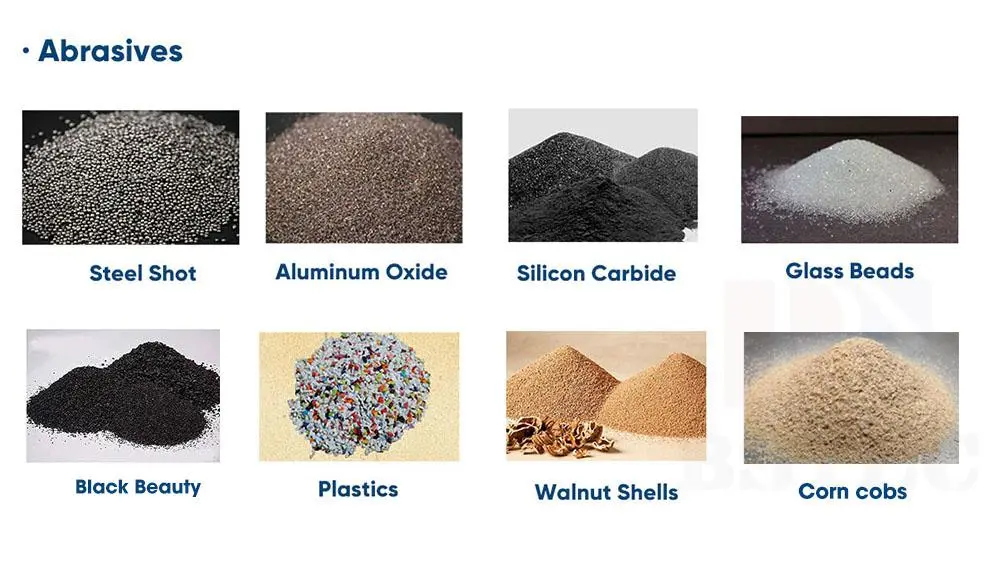

Ukuqhuma ngakunye okuhlukile kwemidiya elimazayo kunezimfanelo zayo ezingaphezu komumo, usayizi, ubulukhuni, nokuminyana. Ukukhethwa kwempahla yemidiya ngokuyinhloko kuncike endaweni elungiswayo noma ephathwayo, hhayi ohlotsheni lwempahla eqhumayo esetshenziswayo. Nansi izinto ezivamile zemidiya ezinukayo ozozithola emisebenzini yokuqhuma kwe-abrasive:

· Isibhamu sensimbi nensimbi yensimbi:Isibhamu sensimbi siyindilinga kuyilapho igrit yensimbi inomumo we-angular. Kuyi-abrasive esebenza kahle kakhulu ngenxa yokuma kwayo kanye nokugaywa kabusha okuphezulu. Ngemisebenzi enzima, akukho okudlula ama-abrasive ensimbi.

· I-aluminium oxide:I-Aluminium oxide ifaka ubulukhuni bayo obuphezulu namandla. Ezindaweni eziqinile ezidinga ukupholishwa kahle, i-aluminium oxide iyimidiya ephelele. Kunzima, kusebenziseka kabusha, futhi kubiza kancane.

· I-silicon carbide:Iyinto enzima kunazo zonke etholakalayo. Le midiya iza ngosayizi ukusuka kumpushana ocolekile ukuya kugridi emahhadla. Ingena kahle ekuhlanzeni indawo eyinselele kakhulu.

· Ubuhlalu bengilazi:Yingilazi ye-soda-lime eyindilinga. Uma kuqhathaniswa nezinye izinto, ingilazi ayinalo ulaka njengemithombo yezindaba eqhumayo njenge-steel shot noma i-silicon carbide. Ama-Abrasives obuhlalu bengilazi anengcindezi encane ngaphezulu ukuze akhiqize ukuqedwa kohlobo lwe-matte ekhanyayo ne-satin.

· Ubuhle Obumnyama:Lena impahla yamalahle slag. Ubuhle Obumnyama bumahhadlahhadla ngokwedlulele futhi bufanele ukugqwala okusindayo nokususwa kopende.

· Ipulasitiki:Ama-abrasives enziwe ngepulasitiki ayahlukahluka ngobukhulu, ukuma, ubulukhuni, kanye nokuminyana. Izinto zepulasitiki zihlanganisa i-polystyrene ne-polycarbonate. I-abrasive ethambile elungele ukwelashwa kwe-fiberglass, isikhunta, noma ukuhlanza izingxenye zepulasitiki.

· Amagobolondo e-Walnut:Amagobolondo ama-walnut amnyama angama-abrasives amahle kakhulu ensimbi ethambile kanye nepulasitiki. Amagobolondo ama-Walnut awabizi futhi atholakala kalula futhi ayavundiswa.

· Izikhwebu zommbila:Njengamagobolondo e-walnut, izikhwebu zommbila ziyi-abrasives ethambile ye-organic. Asetshenziswa ezindaweni ezithambile ukuze asuse ukungcola okufana namafutha, uwoyela, nenhlaka esikhundleni sokugqwala nopende.